|

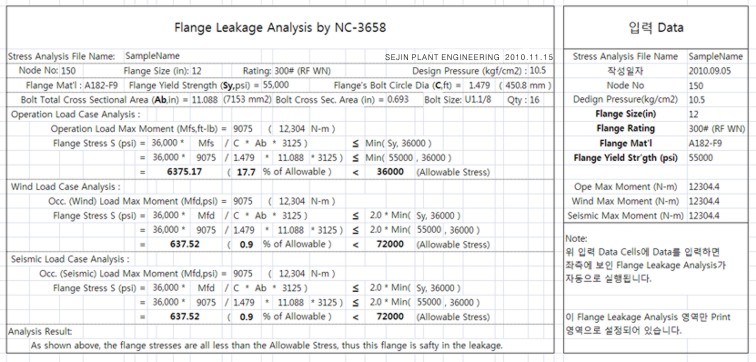

Air-Cooled Heat Exchanger는 케미컬 플랜트에서 아주 많이 사용된다. 이 Exchanger의 Allowable Nozzle Loads는 API STD

661에 규정되어 있는데, 그 값이 매우 작아 이를 만족하는 것이 쉽지 않다. 아래의 글은 중급 이하 모든 Stress Engineer에게

도움을 주고자, 내 후배이기도 하고 또 친구이기도 한 (20년 전, 대림엔지니어링 Stress Engineer로서 나에게 Stress 이론을

주지시키기도 했던) 김x덕씨의 자문을 받아 작성한 것이다.

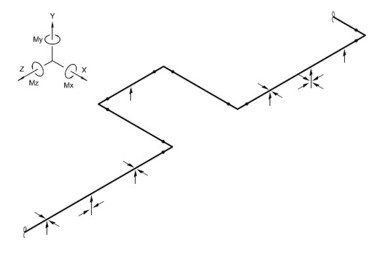

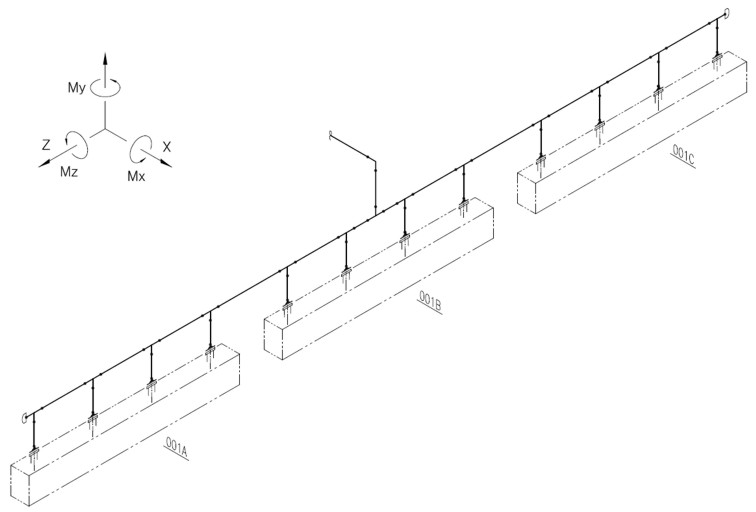

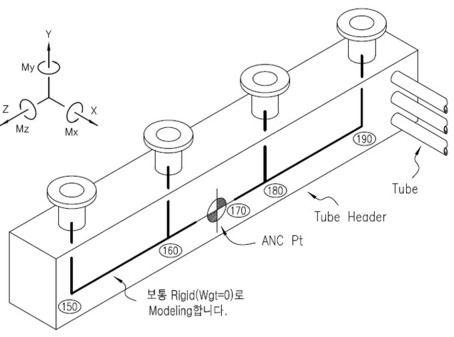

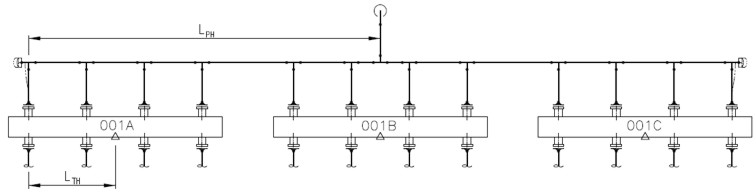

Air Fin Cooler는 대체로 아래에 보인 바와 같은 형상을 하고 있는데, 보통 위쪽 Nozzle로 냉각할 유체(Water)가 입력되고

아래쪽으로 냉각된 유체가 빠져 나가도록 되어 있다. 따라서 Tube Header의 온도는 유입/유출 유체온도의 중간 값을 취한다.

이러한 Air Fin Cooler는 보통 (3,4) 서너 개가 Pipe Rack 맨 위에 설치되고, 이들 Air Fin Cooler의 각 Nozzle은 배관으로

모두 Header에 연결된다.

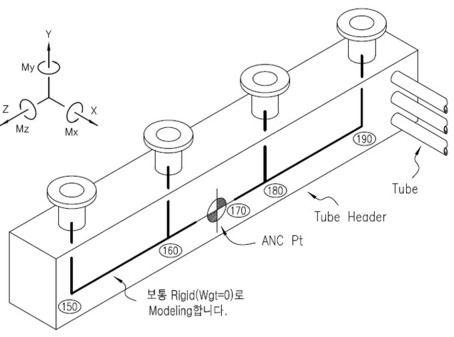

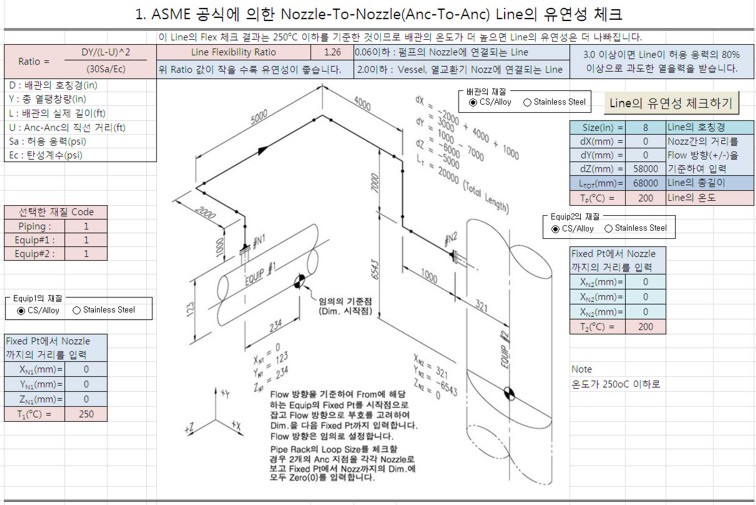

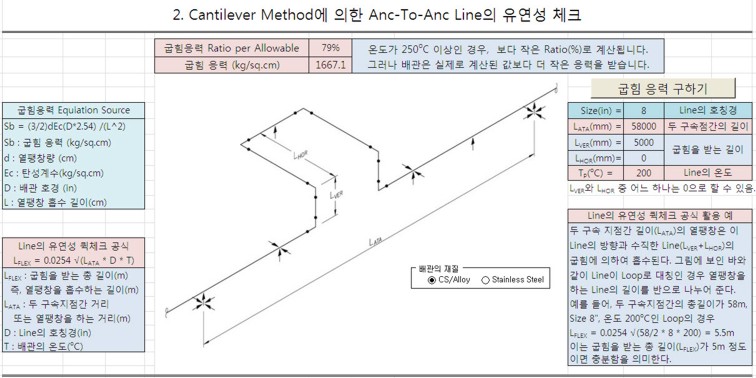

고전적인 방법으로는 각 Air Fin Cooler의 중점(170)을 (ANC) Fixed Pt로 설정하고 Modeling한다. 이 경우, Air Fin Cooler가

3개 이상으로 많고, 또 각 Nozzle과 Header를 연결하는 배관에 유연성(Flexibility)이 부족하면, 맨 우측 Air Fin Cooler의

우측 Nozzle과 맨 좌측의 Air Fin Cooler의 좌측 Nozzle에는 상당한 Load가 걸리게 되어 API-661에 규정한 Nozzle Load를 맞추는

것이 힘들어 진다.

한편, API STD 661에는 아래에 보인 바와 같이 Tube Bundle(Bay)이 이동(Movement)할 수 있도록 되어야 하는 것이 명시되어 있다.

7.1 Tube bundle design

. . . 생략 . . .

7.1.1.2 The vendor shall make provision for lateral movement of exchanger tube bundles of at least 6mm(1/4inch) in

both directions or at least 12mm(1/2inch) in only one direction, unless the purchaser and the vendor agree on a

greater movement.

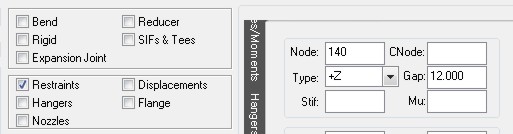

이 규정에 따라 Air Fin Cooler가 얼마간 이동할 수 있도록 Air Fin Cooler의 Tube Header를 Modeling 하면 맨 우측과 맨

좌측의 Nozzle에 큰 Load가 걸리는 것을 피할 수 있다. 아래는 API-661의 규정, 양쪽 6mm (한쪽12mm) Movement을 고려하여

Tube Header를 Modeling 한 예를 보인 것이다.

|

위 그림에 보인 바와 같이, Tube Header의 중점(170)을 CNode ANC로 잡고, CNode 점(171)을 위 그림에 보인 바와 같이

Displacements로 구속한다. 보통 Nozzle의 구속 수단으로 사용되는 Displacements의 구속에서는 빈칸으로 두면 구속되지

않는 상태로 설정된다. 이 기능을 이용하여 Z-축 방향은 자유로운 상태로 설정하고 다음, 맨 우측 Nozzle과 맨 좌측

Nozzle에 연결되는 (Rigid) Header의 Node Pt를 각각 +Z축 방향과 -Z 방향에 대하여 6mm(또는 12mm) Gap을 주고 구속한다.

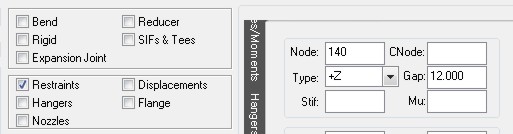

Air Fin Cooler에 유입되는 작업유체의 온도는 그렇게 높지는 않으나 다수의 Air Fin Cooler가 하나의 Header에 연결되고,

Air Fin Cooler의 (위 그림에서 Z-축에 해당하는) 총 길이가 20m를 넘으면, Nozzle이 연결되는 Header의 열팽창 량이

(한쪽으로) 12mm 이상으로 될 수도 있다. 이러한 경우에는 맨 끝 쪽에 위치한 Air Fin Cooler가 12mm를 이상으로 이동하지

못하도록, 아래에 보인 바와 같이, Gap을 12mm로 주고, Z-축을 구속해 주어야 한다. 그리고 응력해석 결과, 6mm 이상의

Movement가 발생한 경우에는 Iso Dwg에 이 Gap을 표시하고, Air Fin Cooler가 (양쪽으로 6mm가 아닌) 한쪽으로만 12mm를

이동할 수 있게 설치(시공)되도록 적절한 수단을 취해야 한다.

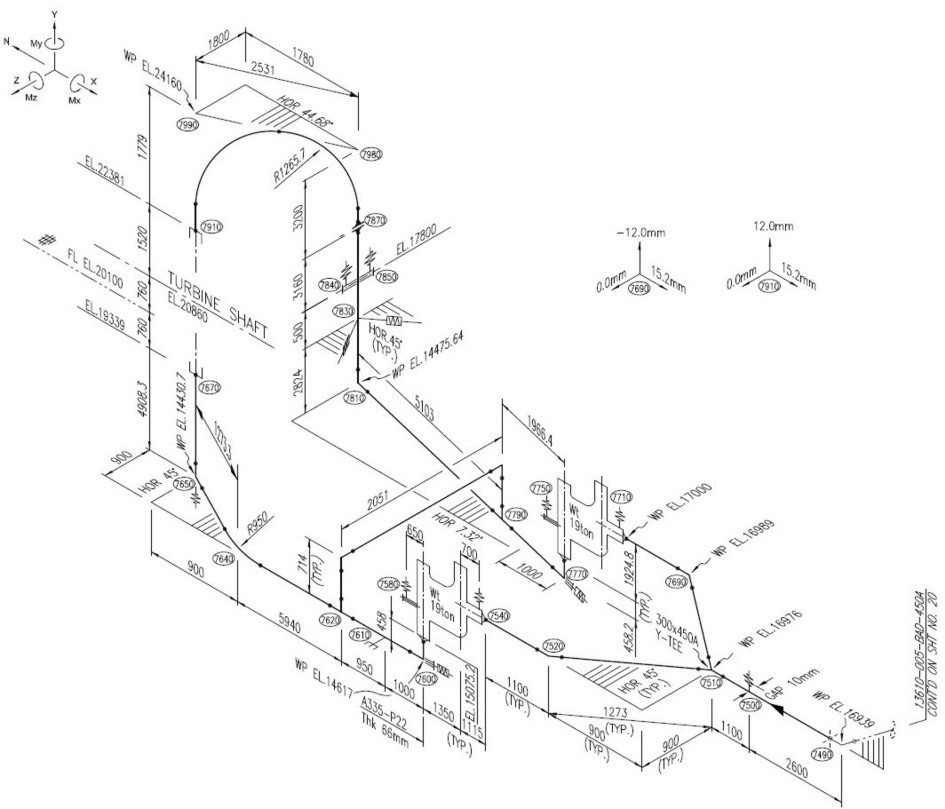

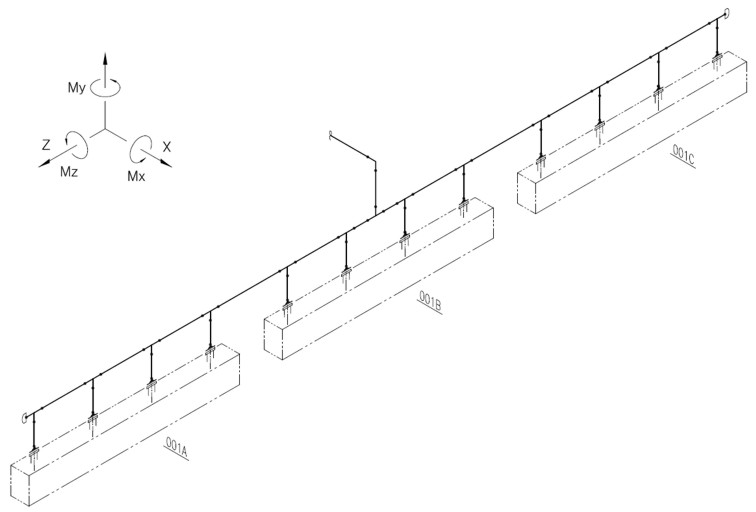

아래의 그림은 Air Fin Cooler 관련 배관의 응력해석에 대하여 보다 쉽게 설명하기 위하여, 냉각해야할 유체가 하나의

Piping Header로부터 3개의 Air Fin Cooler에 유입되도록 의도적으로 구성한, Iso Dwg과 응력해석을 설명하기 위한

Dwgs이다. Air Fin Cooler 배관 System은 아래에 보인 바와 같이 각각 다른 3가지 해석 방법이 사용될 수 있다.

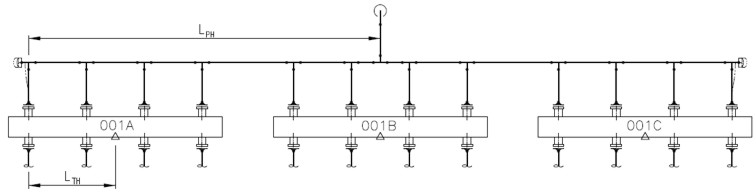

Case-1:

이는 Air Fin Cooler의 Tube Header의 중점을 각각 Z-축에 대하여 구속한 경우이다.

맨 좌측 Nozzle에 대하여 배관 Header는 중점으로부터의 거리 LPH에 의하여 열팽창을 하고, Air Fin Cooler의

Header는 거리 LTH에 의거 열팽창을 한다. 그러므로 배관의 Header가 Tube Header보다 더 많은 열팽창을 하게 된다.

이 경우에는 맨 우측과 맨 좌측 Nozzle에는 열팽창에 의하여 매우 큰 Nozzle Load가 가해진다.

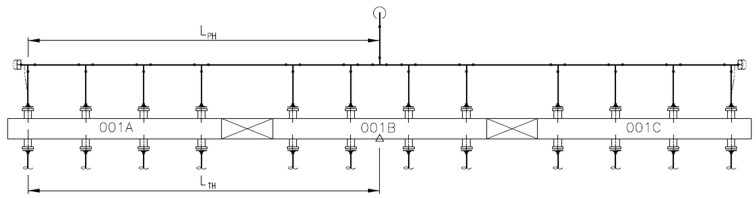

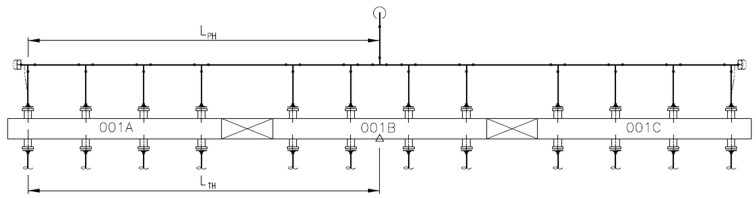

Case-2:

이는 3개의 Air Fin Cooler의 Header를 어떤 Thrust Block으로 모두 연결하고 중앙 Air Fin Cooler의 중점을 Z-축에

대하여 구속한 경우이다.

맨 좌측 Nozzle에 대한 배관 Header의 열팽창 거리(LPH)와 Air Fin Cooler의 열팽창 거리(LTH)는

같다. 그러나 배관 Header의 온도에 비하여 Tube Header의 온도는 좀 낮다. 따라서 열팽창 량은 다르다. 그러므로 이 열팽창

량의 차이에 의하여 맨 좌측과 맨 우측 Nozzle에는, Case-1에 비하여 작기는 하지만, 상당한 크기의 Nozzle Load가 가해진다.

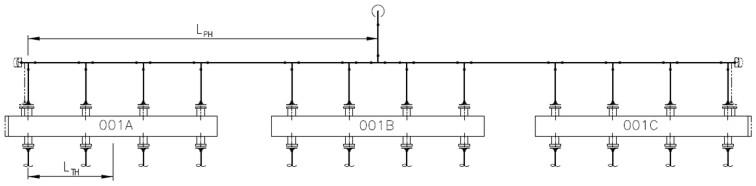

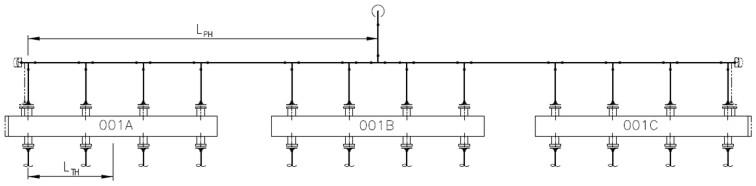

Case-3:

이는 API STD 661 Lateral Movement(6mm/12mm)의 규정에 따라 각각의 Air Fin Cooler가 Z-축에 대하여 움직일 수 있게

구속하지 않는 경우이다.

이 경우에는 배관 Header의 열팽창 거리(LPH)와 Air Fin Cooler의 열팽창 거리(LTH)는 Case-1의

경우와 같다. 그러나 맨 우측의 Air Fin Cooler(001A)는 우측으로 맨 좌측의 Air Fin Cooler(001C)는 좌측으로 이동하게

됨으로, 사실상 Nozzle Load는 열팽창 량의 차, 즉, 같은 열팽창 거리 LTH에 대하여 배관 Header의 온도와

Tube Header의 온도와의 차에 의하여 결정되는 열팽창 량의 차이에 따라 주어진다. 따라서 이 경우에 Nozzle에 가해지는

Nozzle Load는 제일 작은 값이 된다.

이와 같이 Air Fin Cooler의 Tube Header를 Modeling하면 Air Fin Cooler의 Nozzle Load를 API STD 661에 규정한 Allowable

값 이하로 맞추는 데 큰 어려움이 없을 것입니다. 2010.09.05. 양기와

|